English

What are you looking for?

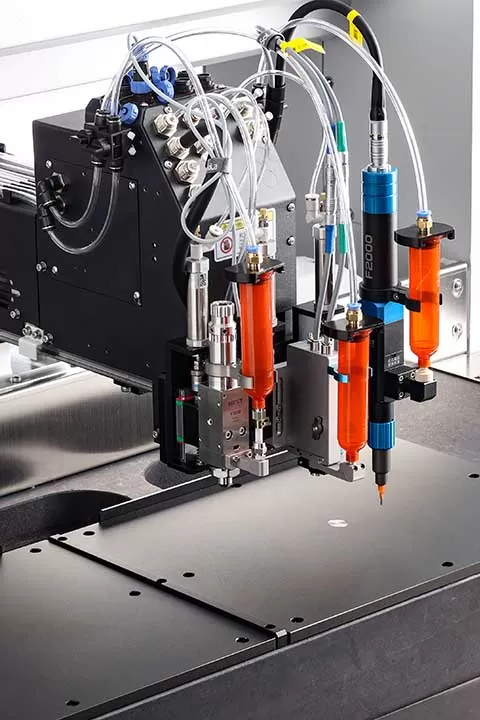

An inline dispensing robot is designed to operate at high speeds, typically capable of keeping pace with modern production lines.

The speed varies based on the complexity of the dispensing task, material type, and application requirements. However, these robots are engineered to dispense materials rapidly without sacrificing precision, often achieving cycle times that match or exceed manual processes.

In high-volume manufacturing environments, they can dispense hundreds or thousands of units per hour, improving efficiency and reducing production bottlenecks. The robots are also adjustable, allowing operators to optimize speed depending on the material's viscosity and the required application quality.

Operators use specialized software to input dispensing parameters, such as material type, flow rate, and speed.

The robot’s dispensing path is defined, often using graphical tools that allow operators to map the exact locations where material should be dispensed.

The automated adhesive dispensing system is calibrated to ensure accurate material application based on the chosen settings.

The system is tested in real-time to ensure consistent, precise dispensing during production.

Adjustments are made to fine-tune the robot’s performance based on production requirements.