English

What are you looking for?

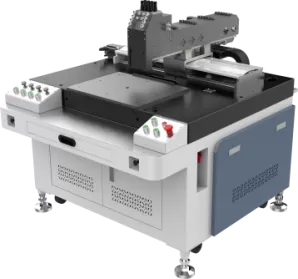

The Panoramic Vision Dispensing Machine MEST-V series, as MEST's flagship dispensing product, has received widespread acclaim in customer dispensing production. As a large-platform high-speed dispensing device, it is equipped with high-definition industrial cameras for automatic precise position recognition, along with CCD detection and positioning correction, ensuring stable, controllable, precise, and efficient dispensing results.

The MEST-V series is suitable for products requiring automatic position recognition and precise positioning. Through high-definition industrial cameras, visual programming, and CCD detection with positioning correction, it achieves recognition of arbitrarily placed products of various shapes, eliminating the need for manual positioning. We can also opt for a dual vision system for secondary visual positioning of product locations, capturing higher-precision product outlines.

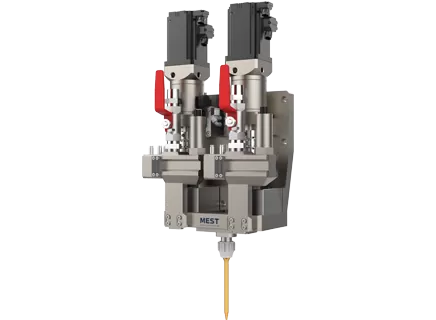

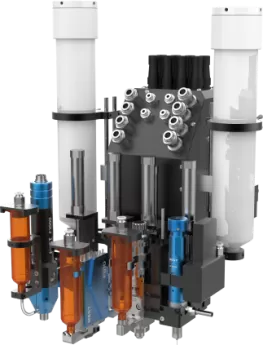

The MEST-V series can install 1-4 glue valves simultaneously, controlled by software for quick switching between valves. Different valves correspond to different adhesives, enhancing production efficiency.

The overall marble base plate provides structural stability. During high-speed operation, it runs smoothly with low noise.

Modular design allows each key component to be disassembled individually, enabling quick replacement of accidentally damaged parts.

The Panoramic Vision Dispensing Machine MEST-V series achieves visual intelligent recognition, automatic trajectory programming, and adaptive product templates. Paired with MEST's independently developed control software, it delivers excellent application results in processes like underfill, trajectory filling, and precision coating. It has been applied in industries such as automotive electronics, 3C electronics, biomedical, security monitoring, semiconductors, and Mini LED.

Images: Mobile Tablets, PCB Boards, Cameras, Badges and Medals

In the production process of mobile and computer panels, dispensing is a key process that directly impacts the connection quality of panel components and the overall product performance.

Using the panoramic vision dispensing machine for dispensing on vehicle display screens allows the screen to be firmly bonded to the vehicle body, reducing external influences like vibration, shock, and temperature changes that could cause loosening. It also enhances the screen's wear resistance, ensuring durability and extending service life.

When coloring badges, medals, and other ornaments, the panoramic vision dispensing machine's vision system automatically recognizes the product, precisely controls the dispensing position and shape, performs high-speed spray painting and coloring, with good flow control and strong airtightness.

If circuit boards are not potted, they can come into contact with air moisture, leading to corrosion. Using the panoramic vision dispensing machine with glue valves for potting on circuit boards completely isolates air and moisture, forming a protective layer on the PCB board. This enhances its vibration resistance and impact resistance, improving the performance and stability of electronic products.

Cameras can also use the panoramic vision dispensing machine equipped with screw valves for dispensing and bonding, fixing lenses and components to prevent loosening or displacement during use, ensuring the camera's imaging quality.

MEST, through its global marketing network and innovative production bases, provides you with exceptionally reliable, high-performance panoramic vision dispensing machines and other dispensing equipment, along with one-stop solutions. See clearly, dispense accurately—choose MEST's panoramic vision dispensing machine to make every drop of glue just right!