English

What are you looking for?

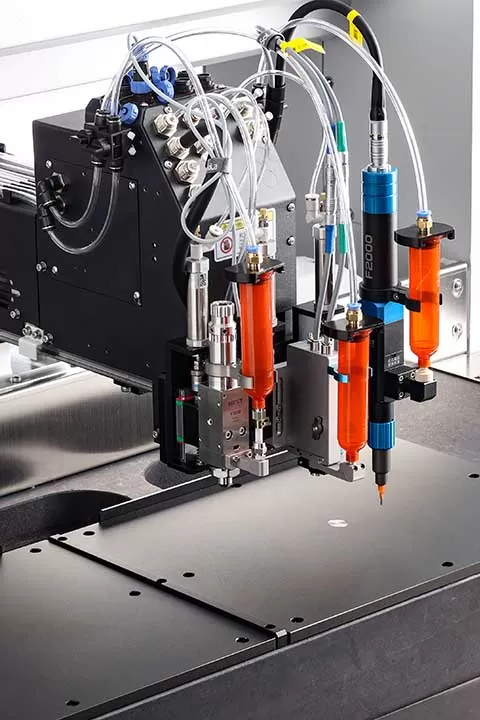

Vacuum dispensing chambers improve product quality by ensuring precise and bubble-free material application. By operating in a vacuum environment, they effectively remove trapped air from materials, preventing defects such as voids or air bubbles in adhesives, coatings, or encapsulants.

This enhances the structural integrity and reliability of the final product. Additionally, the controlled dispensing process allows for consistent material distribution, ensuring uniformity across components.

Vacuum dispensing chambers are particularly beneficial for high-precision applications, such as in electronics or medical devices, where even minor imperfections can compromise performance or durability. This results in superior product quality and long-term reliability.

Vacuum dispensing chambers are equipped with sensors to monitor vacuum levels, ensuring safe and stable operation.

In case of a malfunction or sudden pressure change, an emergency stop feature halts operations to prevent accidents.

Chambers are made with robust materials, such as reinforced steel or aluminum, to withstand high vacuum pressure and ensure operator safety.

The airtight construction prevents leaks, maintaining a controlled environment and protecting users from hazardous material exposure.

Audible and visual alarms notify operators of irregular conditions, ensuring timely action to avoid risks.