English

What are you looking for?

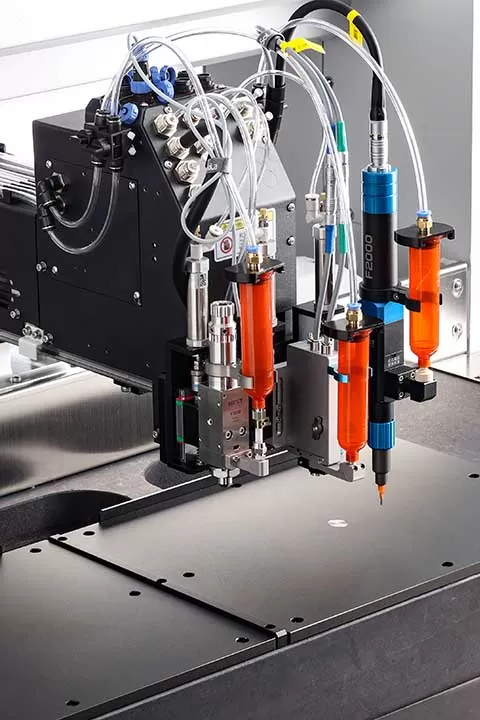

A vacuum dispensing station is designed to precisely dispense fluids or materials while minimizing air bubbles and ensuring uniform application. By creating a vacuum environment, it removes air pockets from the material, ensuring smooth and consistent dispensing.

This is especially important when handling viscous or sensitive fluids, such as adhesives, coatings, or sealants. The vacuum system enhances control over flow rates and volumes, improving accuracy and reducing waste.

Commonly used in industries like electronics, medical device manufacturing, and automotive, a vacuum dispensing station provides higher efficiency, reduces contamination, and ensures reliable results in complex applications.

Vacuum dispensing stations use vacuum pressure to precisely control material flow, reducing air bubbles, while standard stations rely on gravity or mechanical pumps.

Vacuum systems ensure consistent and accurate material application, ideal for high-precision tasks, whereas standard systems may have less control over material placement.

Vacuum stations are better suited for low-viscosity or air-sensitive materials, while standard stations handle a wider range of material types but may introduce air pockets.

Vacuum stations prevent air bubbles, ensuring smooth applications, which is harder to achieve with standard dispensing systems.