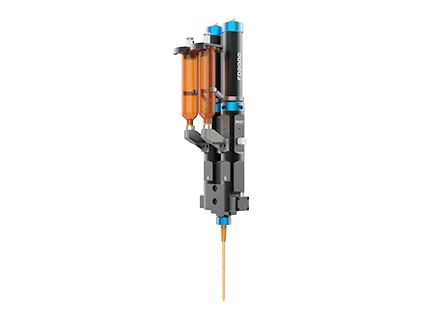

The piezo jet valve has a stable operating frequency of 500Hz and an instantaneous peak frequency of up to 1000Hz.

Our jet dispensing valve can achieve micro dispensing and high-precision glue volume control, with a minimum line width of 0.15mm, and supports non-contact spray dispensing to ensure no damage to the substrate. It is an ideal solution for electronic packaging and precision coating.

MEST piezoelectric valve can dispense glue at high speed in the air, easily dealing with smooth, concave and convex and flexible substrate surfaces. The strong injection pressure is perfectly adapted to high/medium/low viscosity glues, making it the best choice for efficient and precise spraying.

Supports a wide viscosity range of 0~200,000cps, and can stably spray both low-viscosity solvents (such as UV glue/flux) and high-viscosity pastes (such as silicone/conductive glue).

MEST piezoelectric valve can dispense glue at high speed in the air, easily dealing with smooth, concave and convex and flexible substrate surfaces. The strong injection pressure is perfectly adapted to high/medium/low viscosity glues, making our precision dispensing valve the best choice for efficient and precise spraying.

Our piezo pneumatic valve adopts a revolutionary modular flow channel design, which improves maintenance efficiency by more than 90% compared with traditional structures.

English

What are you looking for?