English

What are you looking for?

According to the latest data from the China Association of Automobile Manufacturers, from January to July 2025, new energy vehicle production and sales both surpassed 8.2 million units, with market penetration rising further to 45%. New energy vehicles are increasingly becoming the core driver of transformation in the global automotive industry.

In the surge toward intelligent and electrified vehicles, adhesives have emerged as essential materials in automotive production, fueling high-performance advancements and sustainable, eco-friendly development.

In this edition, we'll explore the most common bonding processes in automotive manufacturing, along with practical solutions.

Adhesives not only strengthen vehicle structures, provide fastening and rust prevention, offer thermal insulation and vibration damping, and enhance interior/exterior aesthetics, but they can also replace traditional methods like welding or riveting for certain parts.

Many adhesives incorporate conductive or insulating fillers, enabling seamless integration of sealing, insulation, and thermal conduction. Additionally, adhesives distribute stress evenly, offering high strength, low cost, and lightweight benefits.

Bonding applications in automotive manufacturing extend well beyond a few key areas. In reality, bonding technology now permeates nearly every aspect of the vehicle—from body structures and the "three electrics" (battery, motor, and control systems) to interior and exterior trims. It spans from chip encapsulation to full structural bonding, ushering in an era where everything is "interbonded."

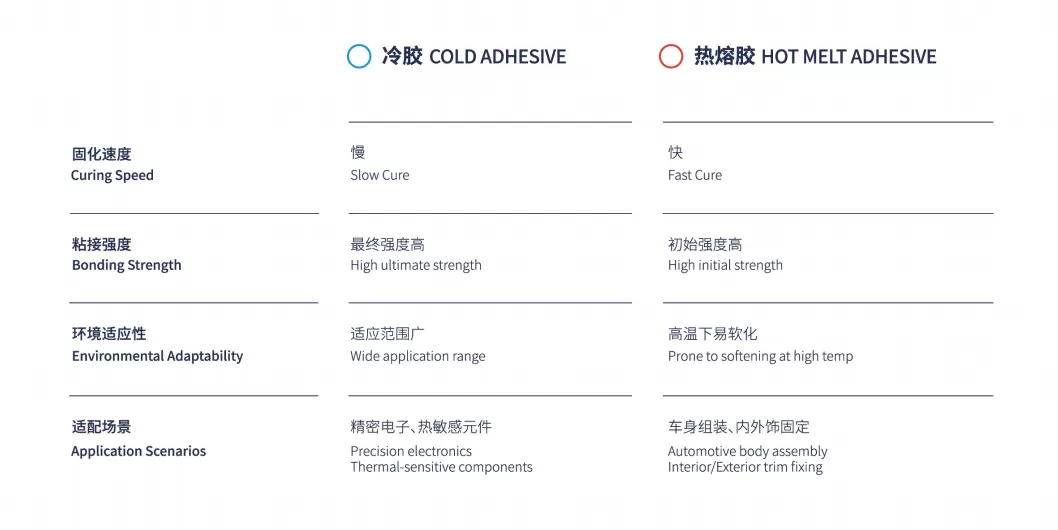

To align with evolving market demands and applications, MEST has gained deep insights into the challenges of vehicle structures and connections. By considering both component and adhesive properties, we've developed two tailored solutions: cold glue and hot glue.

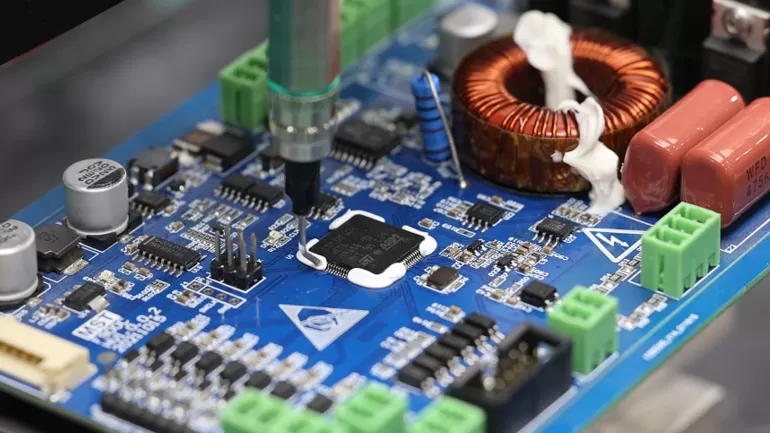

Cold glue solidifies naturally at room temperature, preventing heat damage to sensitive components. Over time, its bonding strength grows stronger, delivering superior sealing. This makes it ideal for precision parts in automotive electronics.

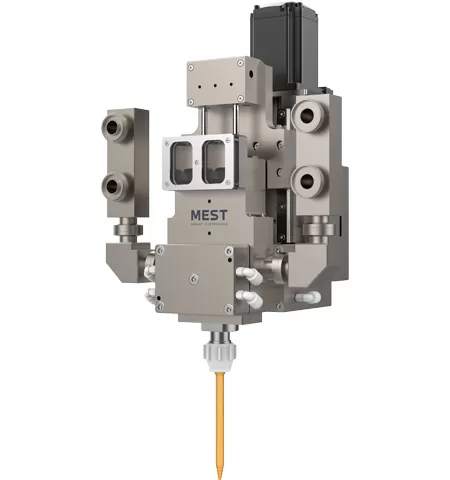

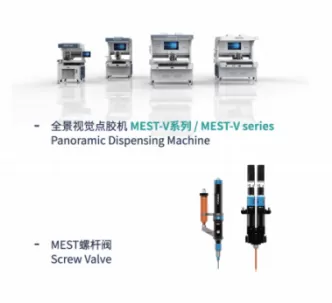

The MEST-V series enables automatic visual positioning, automatic trajectory programming, and adaptive product modules. Combined with our self-developed control software, it is perfectly suited for dispensing in deep and narrow cavities.

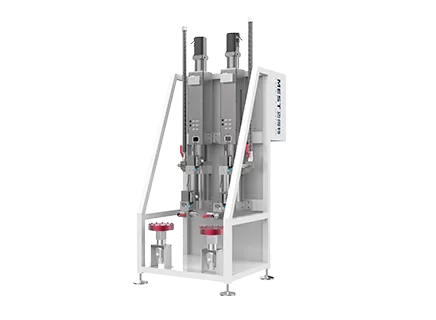

The FD2000 enables precise control over the flow rate and mixing ratio of various two-component adhesives. It is easy to operate, offers accurate output control, and achieves a dispensing accuracy of up to ±2%.

Hot melt glue liquefies when heated and sets rapidly upon cooling. It supports diverse application methods like roller coating, spraying, or scraping, providing significant efficiency gains for high-speed production lines. It's commonly used for body, interior, and exterior bonding, such as headliners (adhering plastic panels), carpets and insulation mats, and mirror assemblies.

The inner surface of the MEST hot melt glue machine glue gun features a Teflon coating to prevent carbonization, ensuring optimal glue quality; the overall design incorporates a precision piston pump for accurate control of glue output; it uses PID intelligent zoned control with independent temperature adjustment; and it includes built-in glue dispensing start protection for high safety performance. Additionally, the glue hose length and glue gun type can be personalized and customized according to the customer's specific requirements.

In automotive production, dispensing technology serves as a microscopic safeguard for electronic system reliability. Through years of expertise, MEST transforms seemingly minor adhesives into the unseen foundation supporting vehicle strength, three-electric protection, and component dependability.

Looking ahead, MEST will continue innovating, refining products and services to meet demands for greater integration and ultimate lightweighting in automotive manufacturing. Stay tuned for more solutions in our next issue!