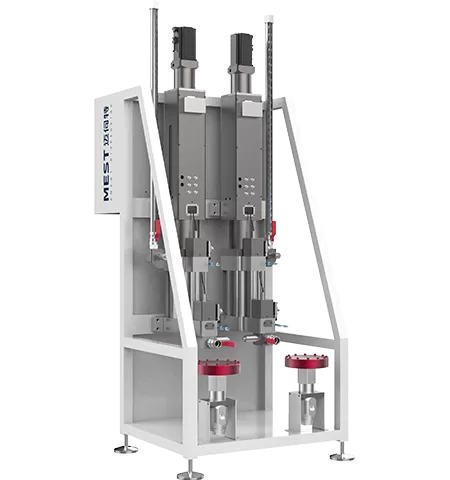

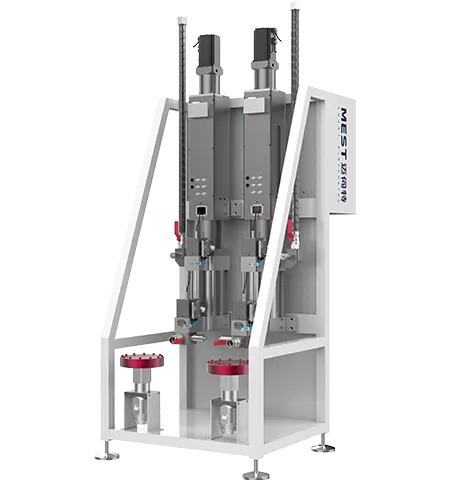

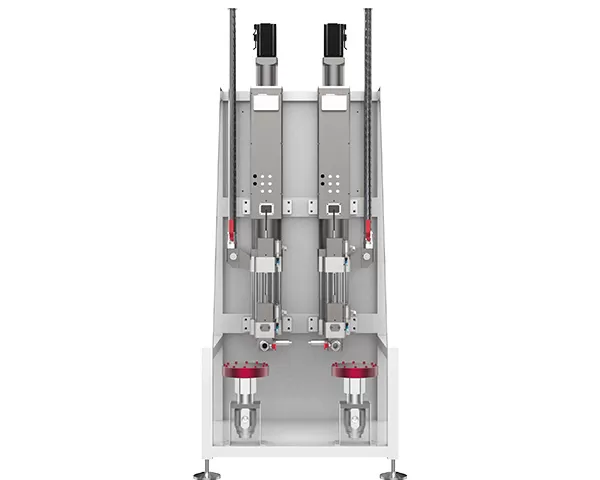

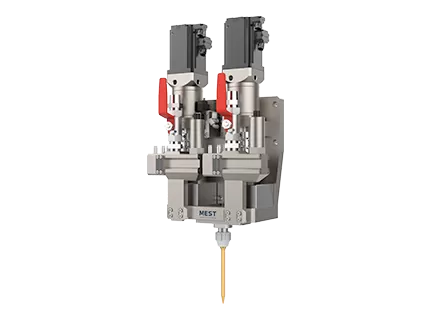

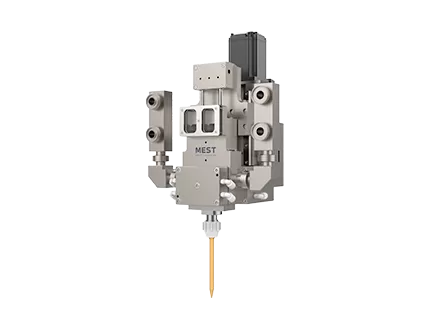

Modular design, easy maintenance. This plunger type metering pump MP50 can be quickly disassembled and replaced without professional tools to avoid cross contamination.

User-friendly UI, meet your multiple-scenario application. Designed by the professional plunger metering pump supplier MEST, one of the leading glue dispensing machine manufacturers, it ensures process stability even for complex fluids (including a high proportion of fillers).

High durability. Unique dynamic sealing technology of the plunger type dosing pump effectively prevents plunger wear caused by filler sedimentation.

English

What are you looking for?