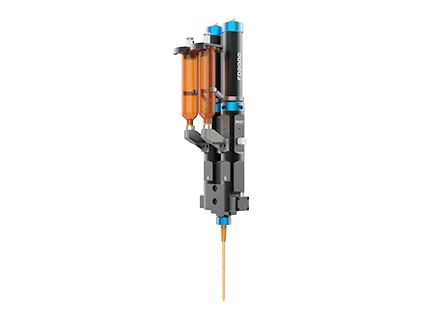

Precision Dispensing Valve – Engineered for Industrial Excellence

200Hz Ultra-High Speed Jet Dispensing – Reduce cycle time & boost throughput in automated assembly lines.

Micron-Level Accuracy (0.2mm Dot Minimum) – Ideal for PCB soldering, microelectronics sealing, and fine-pitch bonding.

Unique Adjustment Mechanism – Seamlessly switch between epoxy, silicone, conductive adhesives & more—no recalibration downtime.