English

What are you looking for?

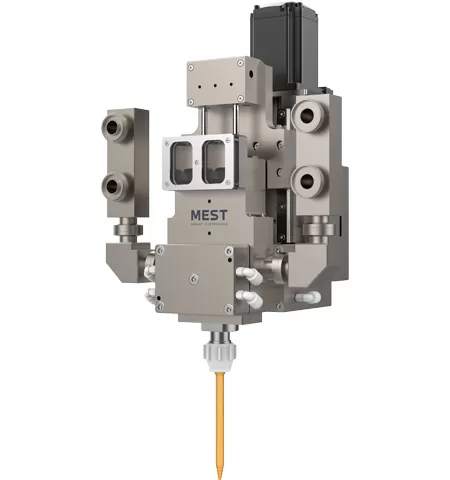

The vacuum potting machine is equipment that performs potting in a vacuum environment. Its most significant feature is its vacuum extraction function, which directly affects product quality. Compared to ordinary potting equipment, the vacuum potting machine can effectively remove bubbles and impurities, ensuring a more uniform and stable potting effect. It is widely used in fields such as automobile manufacturing and capacitor coil potting, and it has good cyclic working capabilities, significantly improving production efficiency.

High Precision Control

The vacuum potting machine is equipped with an advanced control system that can achieve micron-level precision control of potting volume, speed, and path. This high-precision potting system ensures that adhesives are evenly distributed on precision products like electronic components and medical devices, avoiding bubbles and impurities, thereby enhancing product consistency and reliability.

High-Efficiency Production

Compared to traditional manual potting, the vacuum potting machine significantly boosts production efficiency through automated production lines. Automated processes reduce the need for manual intervention, lower the error rate, save time and costs, making it an ideal choice for companies looking to improve production efficiency.

Eco-Friendly and Energy-Saving

The vacuum potting machine uses vacuum technology to remove bubbles and reduce adhesive wastage. Additionally, it features energy-saving designs that lower equipment energy consumption. This not only aligns with green manufacturing principles but also reduces operational costs, achieving efficient and environmentally friendly production.

Wide Applicability

The vacuum potting machine is suitable for multiple industries, ranging from electronics and automobiles to aerospace and medical devices, covering almost all fields requiring precise potting. Whether it is low-temperature curing adhesives or high-temperature weather-resistant adhesives, the vacuum potting machine can handle them with ease, ensuring efficient and stable applications in various environments.

Electronics Industry

In the production processes of electronic products such as mobile phones, tablets, and LED displays, the vacuum potting machine acts as the "guardian" of electronic components, used for potting and fixing electronic parts, ensuring their stability and reliability in complex environments.

Automotive Industry

As the "guarantor" of automotive safety performance, the vacuum potting machine is extensively used in the production of automotive sensors, wiring harnesses, batteries, and other components. It ensures their stability under harsh conditions such as high temperature and vibration through precise potting.

Aerospace

In the manufacturing of aircraft, rockets, and other flying vehicles, the vacuum potting machine serves as the "guardian angel" of flight safety, used for sealing and fixing key components, ensuring they do not leak or loosen during high-speed flights.

Medical Devices

In the production of medical devices, such as pacemakers and endoscopes, the vacuum potting machine ensures device sealing and reliability through precise potting, making it a "model" of precision manufacturing.

As an advanced potting system, the vacuum potting machine not only improves the quality and stability of products across various industries but also enhances production efficiency while reducing energy consumption and resource waste, becoming an important equipment in modern manufacturing.