English

What are you looking for?

In high-pressure applications, the choice of a metering pump can significantly impact the efficiency, reliability, and overall performance of your operations. Piston metering pumps have emerged as the preferred choice for many industries due to their superior precision, robust construction, and versatility. This article delves into the reasons why piston metering pumps excel in high-pressure environments and how they can benefit your business.

Piston metering pumps outperform in high-pressure applications due to their unmatched precision, robust construction, superior efficiency, versatility, and cost-effectiveness. These features ensure reliable operations, reduced maintenance costs, and a significant return on investment.

Understanding the unique advantages of piston metering pumps can help you make an informed decision for your high-pressure applications. Let's explore these benefits in detail.

Piston metering pumps are designed to deliver exceptional precision and accuracy, even under high-pressure conditions. This precision is crucial for applications that require consistent flow rates and exact dosing capabilities. The advanced design of piston metering pumps ensures that they can maintain a steady flow rate, which is essential for processes that demand high levels of accuracy. Whether you are in the pharmaceutical, chemical, or food and beverage industry, the ability to achieve precise dosing can significantly enhance product quality and process efficiency.

The consistent flow rates provided by piston metering pumps ensure that your operations run smoothly without interruptions. This reliability is particularly important in high-pressure applications where any deviation in flow rate can lead to significant issues.

Piston metering pumps offer exact dosing capabilities, making them ideal for critical applications where precision is paramount. This level of accuracy helps in maintaining the integrity of the process and ensures that the end product meets the required standards.

The robust construction of piston metering pumps is one of the key factors that make them suitable for high-pressure applications. These pumps are built with high-quality materials that can withstand extreme pressures and harsh operating conditions. The durability of piston metering pumps reduces the risk of downtime and maintenance costs, providing a reliable solution for demanding applications.

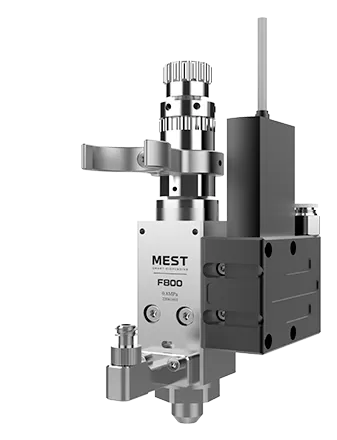

Piston metering pumps are constructed using high-quality materials such as stainless steel and Hastelloy, which enhance their performance and longevity. These materials are chosen for their resistance to wear and corrosion, ensuring that the pumps can operate efficiently in challenging environments.

To further enhance their durability, piston metering pumps can be equipped with specialized coatings that provide additional protection against corrosion and wear. These coatings extend the lifespan of the pumps and ensure that they continue to perform optimally over time.

Piston metering pumps are designed to deliver high efficiency and performance, even under challenging conditions. Their ability to handle a wide range of viscosities and maintain consistent flow rates makes them suitable for various high-pressure applications. The efficiency of these pumps translates to energy savings and reduced operational costs.

The optimized design of piston metering pumps ensures that they operate efficiently, resulting in significant energy savings. This efficiency not only reduces operational costs but also contributes to a more sustainable and environmentally friendly operation.

Piston metering pumps are versatile enough to handle fluids with varying viscosities, making them suitable for a wide range of applications. This capability ensures that the pumps can be used in different industries without compromising on performance.

The versatility of piston metering pumps is another factor that sets them apart in high-pressure applications. These pumps can be customized to meet the specific needs of different industries, from precise chemical dosing to high-volume fluid transfer. Their adaptability ensures they can handle a variety of tasks with ease.

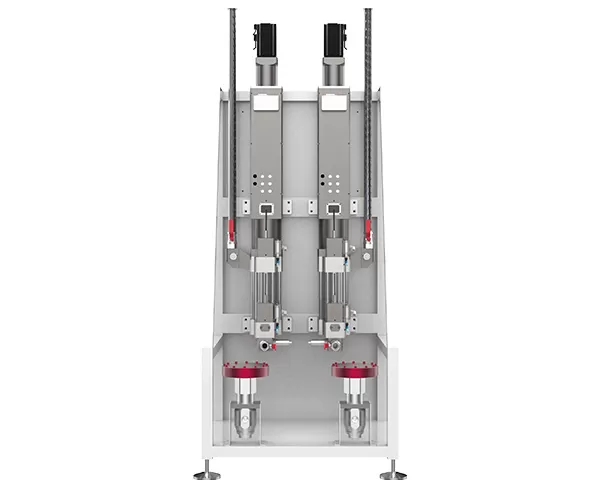

MEST offers a range of customization options for piston metering pumps, including material selection, flow rate adjustments, and specialized coatings. These customizations ensure that the pumps are tailored to meet the specific requirements of your application.

Our piston metering pumps can be seamlessly integrated into your existing systems, ensuring smooth and efficient operations. This integration minimizes downtime and maximizes productivity, making the pumps a valuable addition to your setup.

Investing in piston metering pumps offers significant cost-effectiveness and return on investment (ROI). The reliability, durability, and efficiency of these pumps reduce operational costs and downtime, providing long-term savings. Additionally, the precision and control offered by piston metering pumps ensure optimal use of resources, further enhancing their cost-effectiveness.

The robust design and high-quality materials used in piston metering pumps minimize the need for frequent maintenance, reducing downtime and associated costs. This reliability ensures that your operations run smoothly and efficiently.

The long-term benefits of investing in piston metering pumps include significant cost savings and a high return on investment. The durability and efficiency of these pumps ensure that they continue to perform optimally, providing value for your investment over time.