English

What are you looking for?

Thermal interface materials (TIMs) are vital components in the world of electronics and engineering. They are designed to enhance the heat dissipation capabilities between two hard surfaces, ensuring that devices perform optimally while minimizing the risk of overheating. With electronics becoming increasingly powerful and compact, managing thermal output efficiently is more critical than ever. This comprehensive guide will explore the nature and purpose of TIMs, discussing the various types, their importance in system cooling, and the emerging technologies contributing to their advancement. Whether you're new to thermal management or seeking deeper knowledge as a professional, this article will provide valuable insights into TIMs and their pivotal role in today's technological landscape.

Thermal Interface Materials serve primarily to enhance the thermal conductivity between surfaces in contact with one another in electronic devices and systems. Without them, the efficiency of heat dissipation can be severely compromised, leading to potential overheating. Different devices and setups require different types of TIMs, tailored to specific requirements and constraints.

| Type | Material | Applications |

|---|---|---|

| Grease | Silicone-based compounds | High flexibility, used in uneven surfaces |

| Pads | Silicone-filled, fiberglass | Easy to apply, used for static interfaces |

| Phase Change Materials | Wax-based composites | Transitions from solid to liquid to improve contact |

| Adhesive Tapes | Acrylic or silicone-based | Dual purpose for adhesion and heat transfer |

There are several common types of thermal interface materials each coming with unique properties to suit distinct applications. For example, conductive adhesive often doubles as a glue dispenser in bonding components together, while phase change materials soften upon reaching high temperatures, enhancing thermal conductivity without causing a mess.

Another widely used TIM is adhesive tape, employed not only for adhesion but also for its heat dissipation properties. It's especially popular due to its simplicity in application, albeit sometimes less efficient in heat transfer compared to other methods. Choosing the ideal TIM largely depends on specific requirements such as the die attach process, which is integral in semiconductor packaging to minimize interface resistance and enhance thermal performance.

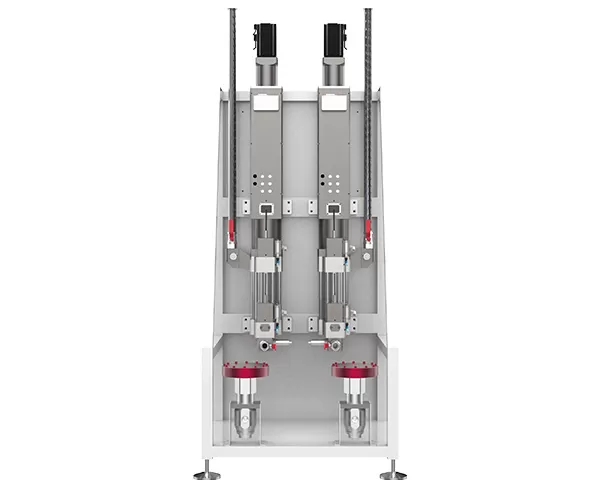

The importance of TIMs in cooling can't be overstated. With the miniaturization of technology, thermal management solutions must adapt. Efficient fluid dispensing systems and thermal interface materials ensure that electronic components remain within safe operating temperatures, thereby extending their lifespan and preserving performance. In manufacturing, equipment like the dispensing machine is pivotal, accurately placing TIMs onto surfaces requiring thermal junction enhancement.

For industries employing machines that dispense TIMs, such as epoxy dispenser or potting machine, the reliable placement of these materials is crucial. Utilizing adhesive dispensing systems that incorporate technological advancements like pneumatic valves or the more refined piezoelectric valve*, can significantly improve production consistency and efficiency.

Recent advancements in thermal interface materials have seen the integration of nano-technology and composite materials to boost performance. Innovations like 2-part epoxy mixing machines and automated gluing processes are driving forward production and application techniques, offering more customized solutions for heat transfer challenges. Progressive cavity pumps, known for their reliability in adhesive dispensing equipment, have also been adapted for precise TIM application, accommodating varied viscosities and compositional complexities.

The ongoing research and development in TIM technologies suggest a future where better performance, affordability, and environmental friendliness coalesce. Improvements in processes like SMT PCB board assembly, orPCB potting for electronics protection, underline the importance of TIMs in maintaining thermal management.

Thermal interface materials are indispensable in the modern landscape of electronics and machinery. They enable efficient heat dissipation, crucial for maintaining functionality and preventing damage due to overheating. By understanding the diverse types, from needle valves and paste dispensing systems to innovative composites, one can select the optimal solution for their application needs, enhancing durability and performance. The ongoing advancements in TIMs, along with refined application techniques, continue to push the boundaries of technology, ensuring that our devices operate efficiently and reliably for years to come.

For more detailed insights into thermal management and TIMs, consider exploring additional resources on thermal properties and advancements within the field.