English

What are you looking for?

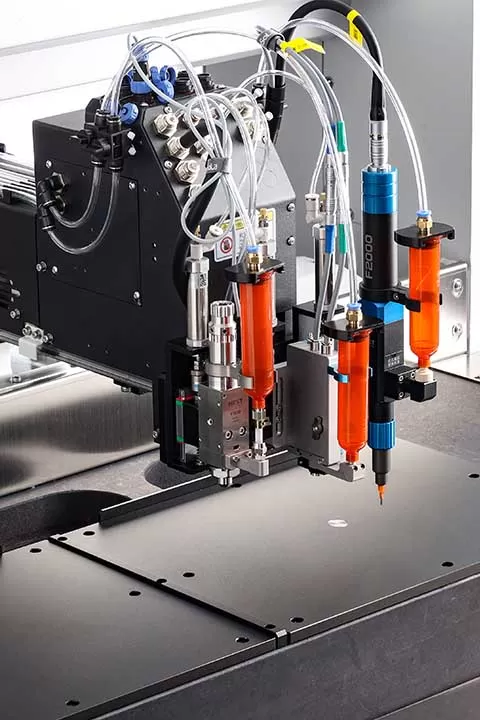

Make sure the Dispensing Head is securely and correctly attached to the container, especially when integrated with a piezoelectric valve system. Tighten it firmly but avoid over-tightening, which can damage the threads or seals.

Regularly inspect the seals and gaskets of the head dispenser for any signs of wear, damage, or misalignment. Replace any compromised components promptly to maintain a tight seal and ensure optimal dispensing performance with our precision dispensing valve.

Opt for dispensing heads with built-in locking mechanisms from leading glue dispensing machine manufacturers to prevent accidental dispensing during transport or storage. Engage the lock when the materials for dispense heads are not in use.

Achieve pinpoint accuracy with every drop, ensuring consistent results and minimizing material waste. Ideal for intricate tasks requiring exact fluid placement in adhesive dispensing systems.

Built with parts sourced from renowned, industry-leading suppliers, guaranteeing durability, reliability, and superior quality you can trust.

Suitable for a wide range of dispensing needs, from electronics and medical devices to automotive assembly, adapting seamlessly to diverse production environments.