English

What are you looking for?

In the realm of electronics manufacturing, heat dissipation plays a vital role in ensuring the stability and longevity of electronic devices. As electronic components become more compact and powerful, managing heat effectively is paramount to prevent overheating and ensure optimal functioning. This guide explores the essential aspects of heat dissipation in electronics, detailing its significance, methods, and advancements. By delving into the components involved, such as conductive adhesives and thermal interface materials, this article aims to provide a comprehensive understanding of how heat management is integrated into electronic manufacturing processes like SMT PCB board assembly and die bonding. Whether you're involved in designing or producing electronic devices, mastering heat management is crucial for achieving high performance and reliability.

Heat dissipation in electronic devices is critical for maintaining functionality and extending the lifespan of components. Excessive heat can cause thermal-induced failures, impacting device performance. Therefore, manufacturers employ various strategies and materials to mitigate these risks. At the core of these strategies are materials and technologies that facilitate efficient heat transfer and dissipation.

Thermal interface materials (TIMs) are commonly used to enhance heat transfer between surfaces in electronic devices. These materials fill the microscopic air gaps between heat-generating components and heat sinks, ensuring more efficient heat transfer. TIMs, including phase change materials and conductive adhesives, are essential in maintaining temperature equilibrium.

| Component | Material | Use in Heat Management |

|---|---|---|

| Heat Sink | Aluminum, Copper | Draws heat away from components |

| Thermal Pad | Silicone, Thermal interface material | Enhances interface contact |

| Conductive adhesive | Silver-filled epoxy | Bonds components while conducting heat |

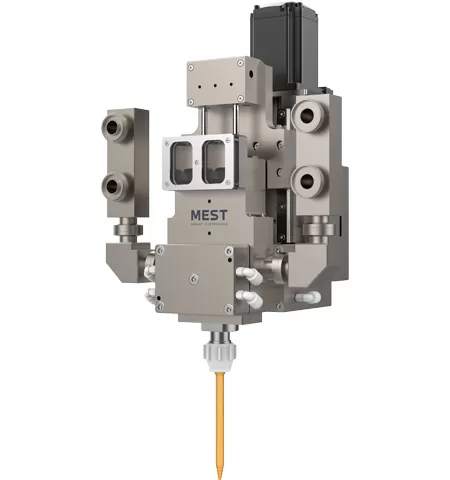

Additionally, advanced dispensing systems play a significant role in applying these materials precisely and consistently. From electronic adhesive dispensing equipment to automated gluing machines, the precision and automation of these systems ensure optimal application, reducing waste and enhancing performance. Customizable dispensing machines tailored for electronic manufacturing offer capabilities such as potting, glass bonding, and PCB potting, further enhancing thermal management.

Material science and technology evolution have significantly contributed to the advancements in managing heat in electronics. Different types of needle valves and metering pumps are engineered to support complex fluid dispensing requirements, ensuring precise delivery of liquid dispensing system components, such as thermal compounds or adhesives.

The use of chemical metering pumps and metering valves enables accurate mixing and application of multi-part adhesives and sealants. Progressive cavity pumps serve as a critical component in operations requiring metering units for even distribution of thermal materials in bulk applications. Tables, such as the one provided below, showcase some of the leading technologies and materials employed in heat dissipation.

| Technology/Material | Application | Benefits |

|---|---|---|

| Dispensing valve | Manages fluid flow rates | Enhances precision and control |

| Piezoelectric valve | Fine control in small-scale applications | Reduces energy consumption |

| Thermal paste | Fills gaps between CPUs and heat sinks | Improves heat transfer |

State-of-the-art dispensing valve systems align with modern manufacturing standards, contributing to sectors demanding high accuracy and efficiency. The inclusion of piezoelectric valves and screw valves demonstrates the trend toward miniaturization while maintaining effective heat management processes.

Manufacturers constantly innovate to enhance the effectiveness of heat management in electronics. Recent developments have made leaps in improving the efficiency and reliability of heat dissipation technologies. Adhesive dispensing systems are now more precise, with configurations available to tackle specific manufacturing challenges, such as 2-part epoxy mixing machines that ensure proper ratios and mixes for robust, heat-managing bonds.

The integration of solder paste inspection tools and automated gluing machinery in production lines ensures reliability and efficiency in applying thermal management materials. These technologies help in maintaining quality control and consistency, especially in mass production environments.

Furthermore, specialized adhesive dispensing robots have been developed for comprehensive duties, from die attach to liquid dispensing in small, intricate devices. Innovations in fluid dispensing systems, including pneumatic valve types that cater to different viscosity requirements, showcase the flexibility and capability of modern equipment in handling diverse adhesive types and volumes.

Successful heat management in electronics relies on best practices that encompass material selection, application techniques, and ongoing maintenance and refinement of systems. Ensuring compatibility and performance of thermal materials within specific devices is crucial.

Effective liquid dispenser machines are calibrated regularly to ensure they meet precise specifications for fluid delivery. When dealing with sensitive components, employing metering units minimizes error margins, preserving material integrity and performance.

| Practice | Method | Outcome |

|---|---|---|

| Regular Calibration | Adjusting machines periodically | Ensures precision in dispensing |

| Material Compatibility Testing | Testing for reactivity with devices | Avoids performance issues |

| Quality Assurance Checks | Consistent inspections | Maintains product standards |

Operations involving barrel pumps for bulk fluid transfers benefit greatly from these practices, yielding consistency across production lines. Whether using durable mono pumps for superior flow control or designing customized potting machines, adherence to best practices ensures optimized heat dissipation.

The role of effective heat dissipation extends beyond simple thermal management; it is pivotal in supporting the applications and long-term usability of electronic devices across industries. From the automotive sector's reliance on efficient dispensing machines for electronic components to consumer electronics, industries demand robust thermal solutions.

PCB potting, frequently used to protect circuit boards, illustrates a widely adopted method in the industry, promoting reliability and longevity. The use of thermal interface materials in aerospace applications emphasizes the critical need for advanced heat management systems.

Moreover, industries are progressively adopting specialized machinery like automated gluing and adhesive dispensing robots to enhance product efficiency and minimize manual errors. Such innovation enables a shift towards smarter, faster, and more reliable manufacturing processes.

The emergence of die bonding techniques, combined with advanced potting electronics methodologies, positions industries to meet ever-evolving technological demands. Transitioning to automated, sophisticated systems ensures businesses remain competitive, delivering top-notch products in a tech-focused marketplace.

Effective heat dissipation remains a cornerstone of successful electronics manufacturing. As devices evolve, the capacity to manage and dissipate heat proficiently becomes increasingly significant. Through a comprehensive understanding of materials like conductive adhesives and advancements in dispensing systems, manufacturers can enhance device performance and longevity. From adhesive dispensing equipment to intricate potting machine designs, deploying the right technologies and strategies is crucial for achieving optimal heat management. Future improvements and innovations promise to drive further efficiencies, resulting in more powerful, longer-lasting electronic devices.

For more information on advanced heat dissipation methods and materials, manufacturers can explore specialized resources and stay updated on technological advancements through industry publications.