English

What are you looking for?

In the realm of modern electronics, connecting components efficiently and effectively is of paramount importance. Conductive adhesives have emerged as a pivotal solution, offering a versatile and reliable method of joining electronic components. This article explores the definition and types of conductive adhesives, their numerous applications in the electronics industry, and how they align with innovative technologies like thermal interface materials and needle valves. By understanding these aspects, professionals and enthusiasts can better appreciate the role of conductive adhesives and strategically incorporate them into their practices.

Conductive adhesives are materials used to join electronic components while allowing the flow of electrical current between them. Unlike traditional soldering methods, conductive adhesives provide mechanical adhesion and electrical conductivity without the need for high-temperature processes. There are several types of conductive adhesives, each suited for different applications and environmental conditions.

| Type | Composition | Applications |

|---|---|---|

| Silver-filled Epoxy | Epoxy resin with silver particles | PCB assembly, die attach applications |

| Carbon-filled Adhesive | Rubber or resin with carbon particles | Potting electronics, grounding applications |

| Polymer Thick Film | Polymer medium with metallic fillers | Surface mount technology (SMT), flexible circuits |

Silver-filled epoxies, for example, are widely used due to their excellent electrical properties and mechanical strength. These adhesives can effectively manage heat dissipation, which is crucial in maintaining the performance of electronic devices. Carbon-filled adhesives, on the other hand, offer a more cost-effective solution where ultimate conductivity is not critical, such as in pcb potting and basic grounding applications.

The electronics industry relies heavily on conductive adhesives, benefiting from their ability to bond components without the thermal stress associated with soldering. One significant application is in die bonding, where adhesives provide a stable connection while accommodating thermal expansion differences between materials.

Moreover, conductive adhesives are integral in adhesive dispensing systems, facilitating precise and repeatable application via automated gluing techniques. These machines that dispense adhesives ensure that each application is uniform, enhancing the reliability of the bond.

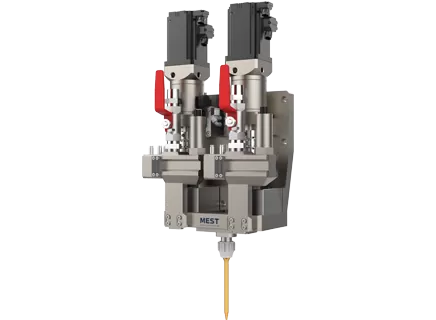

Needle valves and glue dispensers are also essential in this context, offering fine control over the amount of adhesive applied. In environments where precision is paramount, such as solder paste inspection, these tools prevent excess glue application, reducing waste and improving efficiency.

Advanced dispensing machines often integrate metering units and techniques that incorporate pneumatic valves and progressive cavity pumps for optimal control. This versatility allows manufacturers to tailor their application processes, whether handling intricate SMT PCB boards or robust PCB potting for industrial applications.

The integration of thermal interface materials (TIMs) in conductive adhesive applications has further expanded their utility, particularly in thermal management. TIMs enhance the transfer of heat away from sensitive components, minimizing the risk of overheating and enhancing device longevity.

Electronics that must endure high operational temperatures benefit greatly from adhesive-TIM combinations. This synergy is evident in liquid dispensing systems used in high-performance computing and other applications where heat dissipation is critical.

Chemical metering pumps play a pivotal role in ensuring consistent application of these materials, facilitating seamless bonds and thermal conduction. As such, comprehensive dispensing systems often incorporate glass bonding processes alongside TIM applications, supporting a broad range of electronic assembly and maintenance tasks.

Customization is another key advantage of using conductive adhesives. By adjusting the formulation of the adhesive, manufacturers can tailor properties such as viscosity, cure time, and conductivity to meet specific application requirements. This adaptability is invaluable when dealing with diverse projects, from intricate smt pcb boards to large-scale epoxy dispenser applications.

High-precision needle valves are often used to control the flow of these adhesives, ensuring precision in custom applications. In tandem with piezoelectric valves , they allow for meticulous application in sensitive electronics, where even minor discrepancies can lead to significant issues.

Overall, the use of conductive adhesives provides significant flexibility in designing and executing electronic projects. With continued advancements in related technologies such as pneumatic valve types and screw valves, the future prospects for customization in adhesive applications look promising, heralding further innovation in the field.

The field of conductive adhesives is ripe with innovation, particularly as the electronics industry pushes towards miniaturization and higher performance standards. Emerging technologies like 2 part epoxy mixing machines and potting machines promise to revolutionize how these adhesives are applied and utilized, offering greater precision and efficiency.

Meanwhile, the integration of automated adhesive dispensing robots and intelligent control systems enhances production capabilities, providing seamless integration into dispensing machines for a wide range of applications. This progress supports not only traditional electronics assembly but also burgeoning fields like glass bonding and high-density circuit fabrication.

As conductive adhesives continue to evolve, their applications and benefits are likely to expand, offering more robust and versatile solutions for electronic manufacturing challenges. Whether in metering valves for liquid dispenser machines or sophisticated potting machine setups for sensitive electronics, these innovations promise to redefine assembly and maintenance processes in the coming years.

Conductive adhesives represent a cornerstone of modern electronics, providing essential connections that blend mechanical bonding with electrical performance. From efficient heat dissipation management to precise adhesive dispensing equipment, these materials are integral to a myriad of applications, supporting both current demands and future industry advancements.

Understanding the diverse types of conductive adhesives and their specific uses allows professionals to leverage their benefits strategically. With ongoing innovations in thermal interface materials and die bonding processes, the electronics field stands poised for continued elevation through these critical adhesive technologies.

For those exploring the frontiers of electronics manufacturing, conductive adhesives offer a path forward, facilitating new possibilities and setting a foundation for future breakthroughs. By embracing these innovations, companies can enhance product reliability, performance, and adaptability in an ever-evolving landscape.