English

What are you looking for?

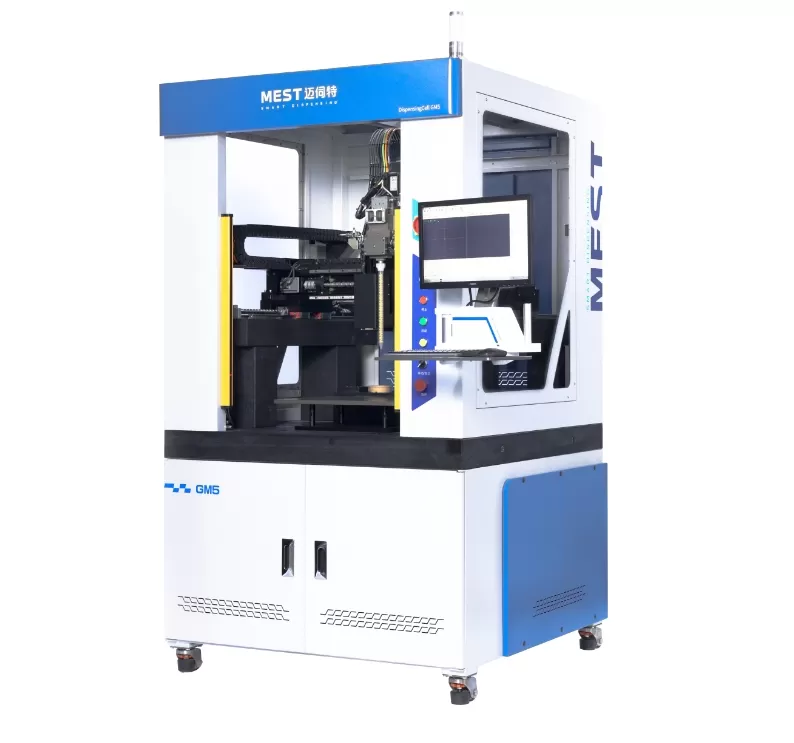

Yes, a dispensing station can be integrated with various other systems to enhance automation and efficiency. Dispense station can be synchronized with conveyors, robotic arms, vision systems, and programmable logic controllers (PLCs) to ensure seamless operation.

Integration of dispensing stations, including chemical dispensing stations, allows for the automatic transfer of materials, precise placement, and consistent dispensing in real-time production. It also facilitates monitoring and adjusting dispensing parameters based on system feedback.

By connecting the dispensing station with other systems, manufacturers can achieve a more streamlined, error-free production process, reducing manual intervention and increasing overall throughput.

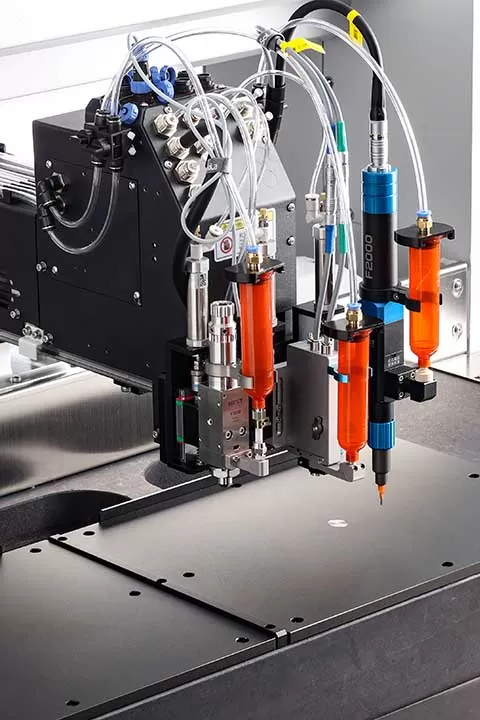

Operators control dispense stations using specialized software or touchscreen panels to set parameters like material flow rate, pressure, and application speed.

Programmable Logic Controllers (PLCs): Advanced robotic adhesive dispensing systems may utilize PLCs for more complex control and automation, allowing precise management of the dispensing process.

Some dispensing stations are equipped with vision systems to verify material placement and ensure accuracy during dispensing.

For automated tasks, dispensing stations can be controlled by robotic arms, ensuring high precision and consistent material application.

Enhanced Precision and Consistency

MEST’s chemical dispensing stations ensure precise and accurate material dispensing, leading to consistent quality control and uniformity in every batch. This precision reduces waste and improves product quality.

Increased Efficiency and Cost Savings

MEST’s dispensing stations automate the process, significantly boosting production efficiency and reducing manual labor. This leads to cost savings by minimizing material waste and lowering labor costs.

Improved Safety and Scalability

MEST’s chemical dispensing stations are designed for safe handling of hazardous chemicals, minimizing spill risks and exposure. They are also easily scalable to meet growing production demands.

Real-Time Monitoring and System Integration

MEST’s advanced dispense stations offer real-time monitoring and on-the-fly adjustments, ensuring optimal performance. They integrate seamlessly with other production systems for improved workflow.