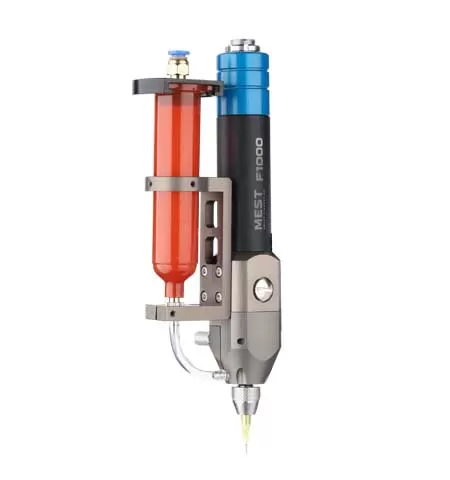

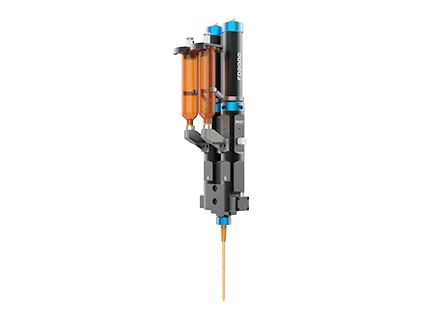

MEST-F1000 screw valve is suitable for dispensing glue with medium to high viscosity, and can be adapted to granular glue.

Precise control and high dispensing repeatability.

The auger valve dispenser can work in narrow gaps of 0.2mm.

Minimum glue output 0.2ul.

The forward and reverse control of the screw is adjustable, the screw sucks back in the reverse direction, and the glue is cut more thoroughly.

MEST-F1000 auger valve dispenser features a modular design, enabling quick disassembly of its flow channel structure – reducing downtime during maintenance.

English

What are you looking for?