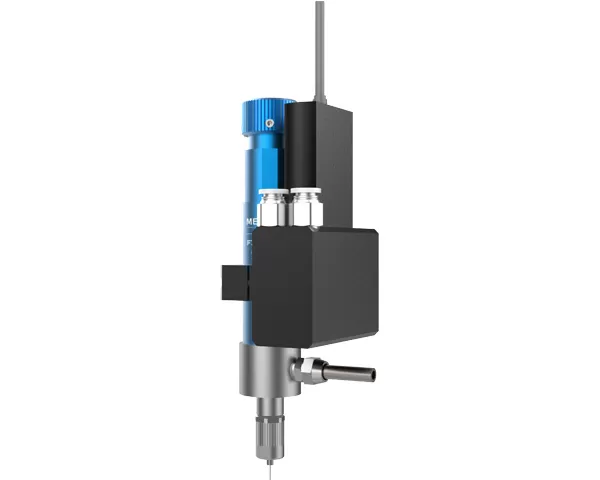

As a key fluid control component, the needle valve plays a vital role in the precision dispensing system with its high-precision flow regulation capability. The needle dispensing valve is a commonly used hydraulic control component, which is composed of a piston, a spring and a needle. When hydraulic flow passes through the pneumatic needle valve body, the hydraulic force moves the needle upward, causing the valve port to open, and hydraulic flow can enter the hydraulic system through the valvebody. When hydraulic flow stops, the spring moves the needle downward, causing the valve port to close, preventing hydraulic flow from entering the hydraulic system. MEST-F700 is a cost-effective micro-volume precision automated needle valve. By adjusting the stroke and adapting to different needles, it can achieve extremely micro-volume, highly consistent dispensing. Suitable for epoxy resin, UV glue, silicone gel, silver pasteconductive glue, ink, grease and other fluids.