English

What are you looking for?

Managing heat in high-power electronics, from industrial motors to EV battery systems, remains a critical yet complex obstacle. Prolonged thermal stress—a common cause of component failure—often leads to diminished performance and costly downtime. Left unchecked, excessive heat accelerates degradation, making efficient thermal management indispensable. While traditional methods like heat sinks and pastes are still used, advanced solutions like thermal conducting dispensing offer superior performance. There are still limitations in conventional cooling approaches, particularly in densely packed PCB designs. Were manufacturers to rely solely on passive cooling, overheating risks would escalate dramatically. Embedded within high-performance applications—aerospace, automotive, and heavy machinery—reliable heat dissipation is non-negotiable. Heat spreads; thus, targeted thermal interface materials must be applied precisely. Proper dispersion of thermally conductive adhesives not only enhances efficiency but also prevents localized hotspots. Only by addressing these challenges early can manufacturers ensure longevity.

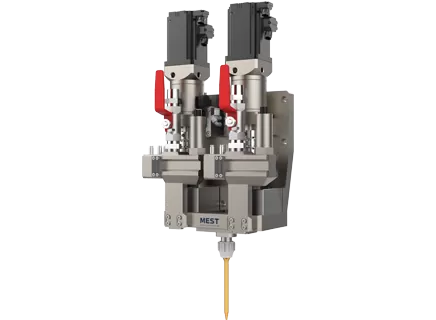

Unlike manual thermal paste application, thermal conducting dispensing ensures uniform, repeatable, and defect-free coverage across electronic assemblies. Automated and precise, this process eliminates air gaps—those silent killers of thermal efficiency—while maintaining optimal thermal conductivity. While manual methods may suffice for low-power devices, high-density power modules demand robotic consistency. Were inconsistencies to creep in, heat distribution would suffer, causing uneven load balancing. There are several key advantages: reduced material waste, superior bond strength, and enhanced thermal transfer. Using highly conductive adhesives—silicon-based or epoxy composites—dispensing systems achieve far greater reliability than traditional approaches. Strategically placed, these materials bridge thermal barriers between components and heat sinks with exacting precision. Were thermal interface materials improperly applied, delamination or hotspot formation could occur. Faster curing and reduced voids further amplify efficiency, making automated dispensing the go-to solution. Precision plus predictability—that’s the power of thermal conducting dispensing.

Achieving peak efficiency means balancing deposition speed with precise material placement—a challenge well-suited for automated dispensing systems. Too much adhesive wastes material, increasing costs; too little risks inadequate thermal transfer. Were dispensing parameters left uncalibrated, process inconsistencies could result. There are multiple factors to consider, including viscosity control, jetting speeds, and needle positioning. Using real-time feedback mechanisms—vision systems and pressure sensors—operators can fine-tune every application. Critical for high-volume production, automation minimizes human error while maximizing throughput. Only with robust software controls can manufacturers guarantee repeatable, high-yield dispensing. Embedded within modern robotics, AI-driven dispensing adjusts dynamically to component variations, ensuring flawless application. Given the stakes—performance, warranty claims, and safety—thermal management processes must leave nothing to chance. Were thermal conducting dispensing neglected, product lifespan would inevitably shorten.

Industrial drilling machines and battery packs share a common nemesis: heat buildup under heavy loads. Subjected to extreme friction and current surges, these systems demand resilient thermal conducting dispensing solutions. While standard adhesives might suffice for mild conditions, industrial-grade applications require specialized materials. There are critical junctions—motor windings, power modules, and busbars—where efficient heat transfer is a must. By integrating thermally conductive adhesives into battery pack assembly, manufacturers prevent dangerous thermal runaway risks. Were these components to overheat, catastrophic failure could follow. Electronics endure; thus, heat must be channeled effectively through precisely applied thermal interface layers. Custom dispensing patterns—zigzag, dot, or serpentine—allow for optimal thermal pathway design. Only with tailored solutions can high-power machinery operate at peak efficiency for years.

From electric vehicles to aerospace electronics, thermal conducting dispensing is revolutionizing heat management. In automotive power modules, the technology enhances longevity, ensuring consistent performance amidst rapid charge-discharge cycles. While passive cooling techniques struggle with compact designs, automated dispensing adapts seamlessly. There are industries—data centers, renewable energy storage, and medical imaging— where thermal reliability is mission-critical. Were manufacturers in these sectors to overlook thermal dispersion, system failures could escalate. Robotics—another high-stakes field—relies on controlled dispensing for motor and drive heat dissipation. Precision-applied thermal adhesives, resisting vibration and thermal shock, extend the life of industrial actuators. Given the evolving demands of 5G infrastructure, thermal conducting dispensing is now indispensable. Heat handled, performance optimized—such is the advantage in next-gen electronics.

Proving durability means subjecting thermal interface materials to extreme conditions—thermal cycling, mechanical stress, and prolonged operation. Without rigorous validation, field failures could lead to costly recalls and warranty claims. Were suppliers to skip accelerated aging tests, long-term performance would remain speculative. There are standardized protocols—MIL-STD-810, AEC-Q200—to verify adhesive resilience under harsh environments. Using advanced spectroscopy and thermal imaging, engineers detect early signs of degradation. Only through continuous monitoring can manufacturers guarantee decades of stable operation. Embedded within R&D processes, failure mode analysis refines next-gen formulations. Were thermal conducting dispensing materials to fall short, entire product lines could falter. Reliability verified, risks minimized—that’s the assurance of certified thermal management solutions.

```