English

What are you looking for?

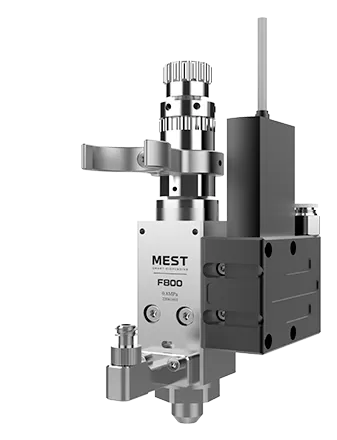

In the fast-evolving landscape of industrial automation, MEST stands as a trusted manufacturer delivering cutting-edge solutions for precise fluid control. Our advanced screw valve technology, including the innovative auger valve dispensing system, empowers industries like electronics manufacturing and automotive assembly to achieve unparalleled efficiency and precision in automated dispensing processes.

MEST’s screw valve is engineered for precision, delivering consistent micro-volume fluid dispensing critical for electronics manufacturing. Whether applying adhesives for circuit board assembly or sealants for component protection, the screw valve ensures exact flow control, minimizing waste and enhancing product quality. Its robust design supports high-speed production lines, meeting the stringent demands of B2B clients.

Designed for compatibility, MEST’s dispensing solutions integrate effortlessly into automated systems for electronics and automotive industries. The screw valve technology synchronizes with robotic arms and conveyor systems, enabling real-time adjustments and reliable performance under high-throughput conditions. This seamless integration reduces downtime and boosts productivity for manufacturers.

In automotive assembly, precision and durability are paramount. MEST company’s screw valve excels in applying sealants and adhesives for battery packs, sensors, and interior components. Its ability to handle high-viscosity fluids with unwavering consistency ensures robust bonding and sealing, supporting the production of next-generation vehicles with enhanced reliability.

MEST’s dispensing solutions are built to withstand challenging industrial environments. Constructed with high-grade, corrosion-resistant materials, our valves accommodate a wide range of fluids, from low-viscosity epoxies to thick sealants. This versatility empowers manufacturers to address diverse application needs, ensuring long-term performance and reduced maintenance costs.

MEST’s commitment to innovation drives efficiency in automated dispensing. Our screw valve technology optimizes fluid delivery with minimal overspray and precise metering, reducing material costs and environmental impact. By streamlining processes, MEST empowers B2B partners to achieve lean manufacturing goals while maintaining the highest standards of quality and consistency.

MEST’s screw valve technology is a cornerstone for manufacturers seeking to elevate their automated dispensing processes. By combining precision, reliability, and versatility, MEST delivers solutions that empower electronics and automotive industries to thrive in competitive markets. Partner with MEST to unlock the full potential of your production line.