English

What are you looking for?

In automotive manufacturing, even micron-level inconsistencies in sealing can lead to costly leaks, corrosion, or warranty claims. With evolving design complexities and tighter tolerances, traditional manual dispensing struggles to keep pace. Here’s how robotic applicators are redefining precision at scale.

Robotic applicators outperform manual dispensing in automotive sealing by eliminating human variability, ensuring 24/7 consistency, and reducing material waste—critical for high-volume production. Their programmable paths adapt to complex geometries, while sensors validate every bead.

But what makes automation the definitive choice for sealing? Below, we dissect the why and how behind the shift.

Despite skilled operators, manual dispensing falters under three pressures: First, human fatigue introduces drift over shifts, risking thin spots or gaps. Second, intricate seams—common in EV battery housings—demand curves that hands simply can’t trace uniformly. Third, with strict VOC regulations, manually controlling sealant volumes becomes unsustainable. There are cases where rework costs exceed 12% of labor hours, often traced to uneven application. Consider this: A 0.5mm deviation in adhesive width might not seem critical—until thermal cycling exposes weaknesses. Unlike robots, humans cannot replicate perfect paths across 10,000 repetitions. Here, automation isn’t just preferable; it’s a corrective necessity.

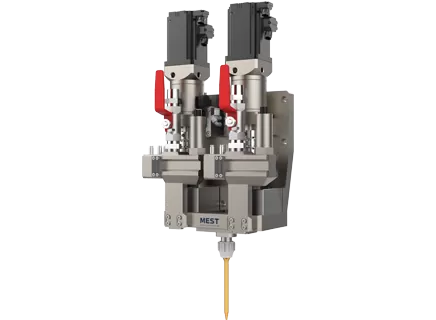

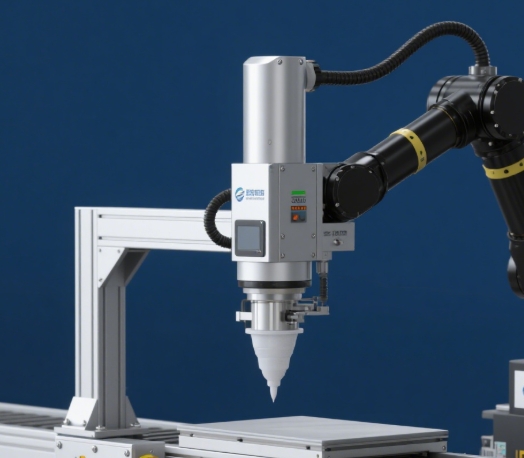

Powered by servo-driven pumps and 6-axis arms, dispensing robots turn precision into a repeatable algorithm. By converting CAD models into toolpaths, they execute flawless beads around door flanges or panoramic roofs—even with 3D contours. Take speed-pressure coordination: where humans adjust manually, robots dynamically tune flow rates mid-bead, preventing tailing or bulging. Embedded with vision systems, these tools self-correct for panel gaps, something no training can guarantee for workers. There’s also the matter of downforce: where human wrists might waver, robots maintain 2N ±0.1N pressure relentlessly. Result? Zero-defect seals that pass immersion tests 100% of the time.

Measured side-by-side, robotic systems reveal their edge in three KPIs: Cycle time drops by 30–50%, as robots dispense continuous beads vs. human stop-start motions. Meanwhile, scrap rates plummet from ~5% to under 0.8%, thanks to exact material placement. But the hidden win? Changeovers: Whereas manual setups require trial-and-error adjustments, robots store recipes digitally, cutting downtime by 90%. There are lines where one robot equals four operators’ output—without overtime or ergonomic risks. Small wonder Tier 1 suppliers increasingly mandate automation for sealing.

Retrofitting robots into legacy lines need not mean overhaul. With modular mounts and PLC interfaces, most systems dock into conveyors within weeks. Critical is the “teaching” phase: Using offline programming (OLP), engineers simulate paths before deployment, minimizing line stoppages. There’s flexibility too—should a new model launch, robots reprogram faster than trainers can upskill crews. Take BMW’s Spartanburg plant: After integrating robotic sealant units, their mix-to-mix changeovers shrunk from 40 to 8 minutes.

Every excess gram of sealant squandered by manual variance adds up—often to 15–20% overuse annually. Through flow control, robotic applicators meter adhesives to ±1% accuracy, slashing waste while maintaining joint integrity. There’s also the elimination of “just-in-case” over-application—a common human habit. In a 2023 audit, one OEM reported saving 37 tons/year per line after switching to robots. Less waste means fewer replenishment orders, lowering both costs and carbon footprints.

Beyond today’s gains, three innovations loom: AI-driven adaptive sealing will self-optimize paths based on real-time camera feedback. Then come self-healing sealants, demanding robotic precision to activate chemistries exactly. Finally, cobots may handle final inspections, pressing seals with calibrated force to ensure adhesion. Already, startups are testing nanoliter-level dispensing for micro gaps in solid-state batteries. For suppliers hesitating on automation, the question isn’t “if” but how soon to onboard.

In automotive sealing, the gap between “acceptable” and flawless is where recalls are born. Robotic applicators don’t just close that gap—they erase it algorithmically. Ready to upgrade your process?