English

What are you looking for?

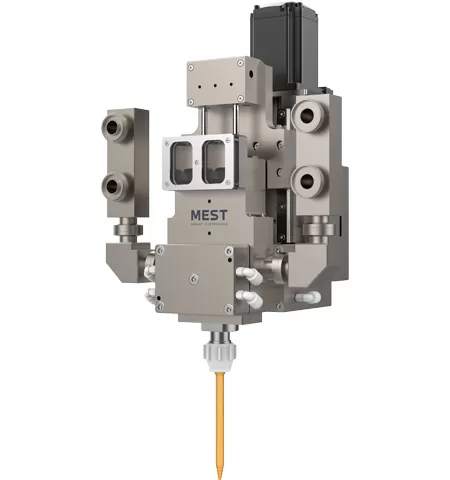

Pneumatic metering pumps are widely used in various industries for their reliability and precision. However, like any equipment, they come with their own set of challenges. From clogging issues in high-viscosity applications to ensuring durability against corrosive chemicals, addressing these challenges is crucial for maintaining efficient operations. This guide provides practical solutions to common problems associated with pneumatic metering pumps.

To effectively solve these challenges, it's essential to focus on key areas such as preventing clogging, improving dosing precision, selecting durable materials, minimizing maintenance, ensuring safety in hazardous environments, and optimizing system integration. By addressing these aspects, you can enhance the performance and reliability of your pneumatic metering pump.

Clogging is a common issue in high-viscosity applications, but it can be mitigated with the right strategies. First, ensure that the pump is designed to handle high-viscosity fluids, featuring larger internal passages and robust suction capabilities. Regular maintenance, including cleaning and inspection, can also help prevent buildup that leads to clogs. Additionally, using pre-filters can remove larger particles before they enter the pump, reducing the risk of clogging. By implementing these measures, you can maintain smooth and efficient operation.

Improving dosing precision in pneumatic metering pumps is essential for accurate chemical delivery. Advanced control features, such as digital interfaces and programmable settings, allow for precise adjustments and monitoring. Additionally, incorporating feedback mechanisms, like flow meters and pressure sensors, can provide real-time data to ensure consistent dosing. Here’s a comparison of control features:

| Control Feature | Benefits | Limitations |

|---|---|---|

| Digital Interfaces | Easy adjustments, precise control | Requires training, potential for complexity |

| Programmable Settings | Customizable dosing schedules, automation | Initial setup time, potential for errors |

| Feedback Mechanisms | Real-time monitoring, improved accuracy | Additional cost, potential for sensor issues |

By leveraging these technologies, you can achieve higher dosing precision and improve overall system performance.

Material compatibility is crucial for ensuring the durability of pneumatic metering pumps, especially when handling corrosive chemicals. Stainless steel, PTFE, and specialized plastics are commonly used materials that offer excellent chemical resistance. Selecting the right material based on the specific chemicals being handled can prevent corrosion and extend the lifespan of the pump. Additionally, regular inspection and maintenance can help identify and address any material degradation early, ensuring long-term reliability.

Minimizing maintenance and downtime is essential for maintaining efficient operations. Choose pumps that are designed for easy access and maintenance, with features such as quick-release components and clear maintenance guidelines. Regular preventive maintenance, including cleaning, lubrication, and inspection, can help identify potential issues before they lead to failures. Additionally, having a reliable supplier who offers comprehensive support and spare parts can ensure quick resolution of any problems, reducing downtime and maintaining productivity.

Pneumatic metering pumps are often used in hazardous environments due to their intrinsic safety features. These pumps do not generate heat or sparks, making them suitable for explosive or flammable atmospheres. Additionally, selecting pumps with robust construction and materials that can withstand harsh conditions further enhances safety. Ensuring proper installation, regular maintenance, and adherence to safety guidelines can mitigate risks and ensure safe operation in hazardous environments.

Optimizing system integration is crucial for seamless operation of pneumatic metering pumps. This involves ensuring compatibility with existing systems, such as control panels and monitoring equipment. Using standardized connections and interfaces can simplify integration and reduce setup time. Additionally, working with a supplier who offers comprehensive support and customization options, such as MEST, can help tailor the pump to your specific needs. By focusing on seamless integration, you can enhance overall system efficiency and reliability.